In today’s fast-paced industries, precision and efficiency are crucial for success. The Keyence 3D Profiler has become a game-changer, offering highly accurate, non-contact 3D measurements that revolutionize processes across various sectors. Let’s explore what makes this innovative device so impactful and why businesses are relying on it to stay ahead of the competition.

What is the Keyence 3D Profiler?

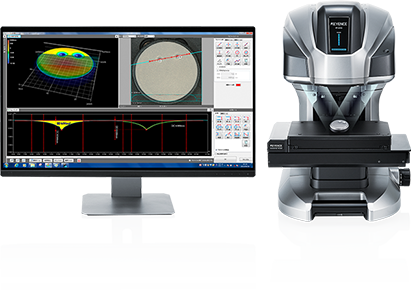

The Keyence 3D Profiler is an advanced measurement device designed to capture three-dimensional data of objects with exceptional accuracy. Unlike traditional tools, this profiler uses laser-based scanning to create detailed 3D representations of surfaces without physically touching them. Whether for quality control, product development, or research, the profiler is a reliable solution for diverse needs.

You can learn more about the Keyence brand and its innovative technologies on their official website.

Key Features of the Keyence 3D Profiler

The profiler stands out due to its groundbreaking features:

- High-Resolution Scanning: Captures intricate details, even on complex surfaces.

- Non-Contact Measurements: Prevents damage to delicate or fragile materials.

- Real-Time Analysis: Enables immediate inspection results to save time.

- User-Friendly Software: Allows seamless integration with existing systems.

How Does It Work?

The device uses laser triangulation technology to measure distances between its sensor and the object’s surface. These measurements are then converted into a 3D image that can be analyzed for defects, dimensions, or surface irregularities.

For a deeper dive into the technology, check out this informative guide.

Applications of the Keyence 3D Profiler

Industries worldwide are benefiting from the profiler’s capabilities:

- Manufacturing: Ensures components meet precise specifications.

- Automotive: Enhances safety by verifying part dimensions.

- Electronics: Detects micro-defects in delicate parts.

- Medical Devices: Guarantees compliance with stringent standards.

Discover real-world examples of its applications on Control Engineering.

Advantages of Using the Keyence 3D Profiler

- Improved Accuracy: Minimize errors in measurements for better product quality.

- Increased Efficiency: Speed up inspections without sacrificing precision.

- Cost Savings: Reduce waste and avoid costly rework by detecting issues early.

- Versatility: Suitable for a wide range of materials and industries.

Learn more about these advantages at Quality Magazine.

Why Should You Invest in a Keyence 3D Profiler?

For businesses aiming to improve their operations, the Keyence 3D Profiler is a must-have tool. By integrating it into your workflow, you can achieve consistent results, enhance productivity, and maintain a competitive edge.

If you're considering investing in one, explore customer reviews on Tech Insights.

Conclusion

The Keyence 3D Profiler is more than just a measuring device—it's a comprehensive solution for industries that demand precision and innovation. By adopting this technology, companies can overcome challenges, optimize processes, and ensure their products meet the highest standards.