The Zygo Profilometer has become a critical tool in modern industries that require precision surface measurements. From optics to semiconductors and manufacturing, this tool delivers accurate, non-contact surface profiling, which is essential for ensuring product quality and reliability.

What is a Zygo Profilometer?

A Zygo Profilometer is an optical metrology instrument used to measure the surface topography of an object. It is especially valued in industries where high-precision measurements are crucial. The profilometer uses interferometry to assess the shape, roughness, and flatness of surfaces without touching them. This non-contact method ensures accuracy without damaging sensitive surfaces. More about interferometry can be learned from Interferometry.com.

Key Features of the Zygo Profilometer

Non-Contact Measurements:

One of the most significant advantages of the Zygo Profilometer is its ability to measure surfaces without making any contact. This feature is particularly important when dealing with delicate materials like optical lenses or fragile semiconductor wafers.High-Precision Surface Profiling:

The device uses laser interferometry to provide extremely accurate measurements, down to nanometer resolution. This level of precision makes it indispensable for industries that rely on exact surface specifications. Zygo Corporation has perfected this technology, making it the preferred choice for professionals in precision industries.Versatility:

The Zygo Profilometer is used across various sectors, including aerospace, automotive, and medical device manufacturing. Its ability to measure a wide range of surface types and shapes makes it highly versatile. From smooth optics to rough mechanical parts, it can handle them all with ease. Find out more about profilometry applications on Metrology News.3D Surface Mapping:

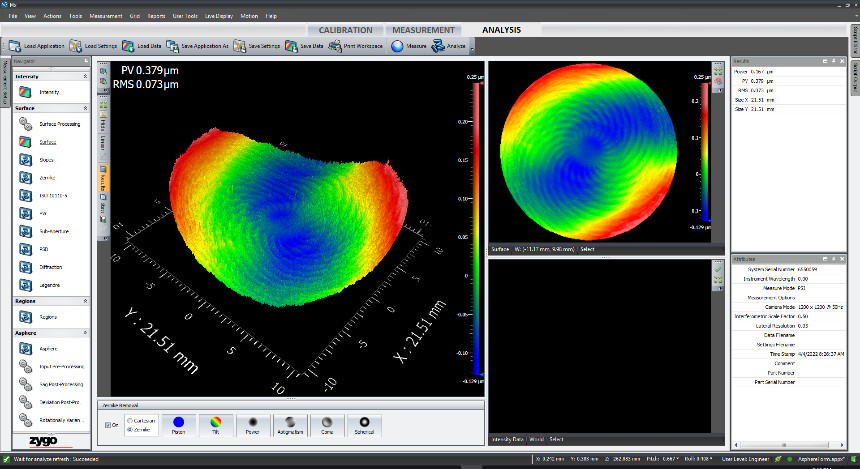

One of the standout features is the ability to generate 3D maps of surface topography. This is particularly useful for quality control in manufacturing, allowing engineers to detect microscopic defects that could affect the final product. Learn more about its capabilities on Zygo's official website.

Applications of the Zygo Profilometer

Optical Industry:

In the production of optical lenses and mirrors, surface accuracy is vital to ensure proper light transmission. The Zygo Profilometer allows manufacturers to check for surface roughness and defects that could distort optical performance. More details on its impact in optics can be found on Optica.org.Semiconductor Industry:

Semiconductor wafers need to be incredibly flat to function correctly. The Zygo Profilometer provides the high-resolution surface mapping necessary to meet the stringent requirements of this industry. It also helps in detecting surface irregularities that may impact the performance of chips. For more on semiconductor applications, visit Semiconductor Engineering.Medical Devices:

Medical device manufacturers, especially those producing implants or surgical tools, rely on precision surface measurements. A profilometer ensures that these devices meet stringent standards, reducing the risk of failure or complications during use. Explore more about medical applications on MedTech.

Why Zygo Profilometer Stands Out

What makes the Zygo Profilometer stand out from other measurement tools is its accuracy and reliability. Unlike traditional contact-based tools, this non-contact instrument reduces the risk of wear and tear on both the measuring device and the material being tested. Moreover, the profilometer’s ability to create high-resolution 3D maps makes it invaluable for detecting microscopic defects. Learn more about the advantages of non-contact measurements from Nanovea.

With a wide range of applications in industries where precision is critical, the Zygo Profilometer continues to set the standard for surface measurement. It ensures that products meet quality control standards, ultimately reducing waste and improving production efficiency.

Conclusion

Whether you're in the field of optics, semiconductors, or medical device manufacturing, the Zygo Profilometer is an essential tool for ensuring surface accuracy. Its non-contact, high-resolution capabilities make it a favorite for precision industries, helping manufacturers deliver reliable and high-quality products.